In an interaction with Sifydotcom, a senior Nasscom leader explains the benefits for Indian manufacturers to consider Industry 4.0 standards

When Klaus Schwab, the executive Chairman of the World Economic Forum spoke on the concept of Industry 4.0 an aura of innovation and automation is all that he had hinted on. In the pandemic days, with the growing rise of digital, enterprises from industries such as manufacturing, pharmaceuticals, retail and even banking were compelled to relook their Industry 4.0 strategies.

Even as industries have readily transitioned from human-assisted processes to automated ones, the potential for better automation and more innovation is believed to improve business margins. Little wonder that scientists and even leaders believe that Industry 4.0 is the arrival of the “Imagination Age”.

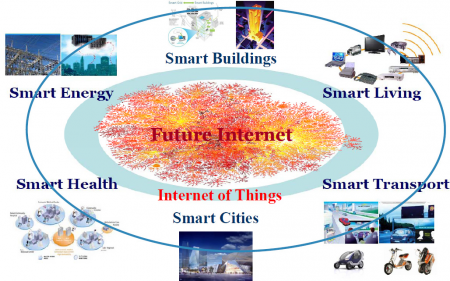

In the imagination age, businesses can ponder alternate realities. For instance, a few years ago, not many imagined the emergence of OTT platforms. Similarly, many who thought of the smartphone as a mere communication tool never really believed that it would one day take orders and even help us travel through the maze of traffic within the city. Besides TVs, Air-conditioners, refrigerators and even cities, there is a greater consensus on making the enterprise smarter. Amit Saluja believes that VUCA (Volatile, Uncertain, Competitive, Ambiguous) times bring about a compulsion to expand capacities. Saluja is a Senior Director Head of NASSCOM center at Gandhinagar. He has held leadership positions at IBM, General Electric, and RPG Transmission in a career spanning over 25 years.

In a conversation with Prasanna Kr Srivastava, he hints that Technology is the orchestrator that enables organizations to reimagine multiple possibilities. Here are edited excerpts from a conversation.

Why industry 4.0 and how different is it from the previous industrial revolutions?

Every Industry revolution has brought in a transformative change to manufacturing, while new technology has been the common element and backbone for every revolution but 4th Industry revolution has even more in it. Biggest difference between the current and past industrial revolution is that focus now is on organizational level transformation not just the manufacturing function which used to be the case with earlier revolutions. We are talking about connected systems that enables machine and human talk to each other with both taking decisions, not just the human. The impact is visible across functions including supply chain, procurement, logistics and even customer engagement. AI, IoT and Analytics has given us the power to predict, thereby making ourselves ready for the future challenges.

Where do you see India at this fourth revolution? Have we been late to shift?

We are indeed late to shift. Speed at which technology is evolving is much more than our current rate of change. Covid has given us a reality check to people who were sitting on fence earlier. There is enough data to prove companies who adopted digital before covid fared better during the pandemic. Thanks to startups who have evolved in last few years, we have enough solution providers now to support the large number of manufacturing units in the country. Awareness level of the manufacturing leaders is also much better and they are asking for help to get guidance on digital adoption.

In which parts of the economy is Industry 4.0 being implemented in India, and is this really impacting their ROI?

All large manufacturing enterprises started their digital journey few years back already and they have become even more proactive now to adopt new solutions. Biggest change we see is the mid-size sector (typically between 1000 to 5000 crore companies) with the realization that industry 4.0 is no more of an after-thought. They have also realized that RoI based projections should not be the only factor for considering such deployments. We are living in a VUCA world where these uncertainties will continue to happen and being prepared is the only solution. Payback period of software led solutions will always be less than the pure hardware led solutions, so if companies find ROI in investing in machines and high-end equipment, they always will find it better with Industry 4.0 solutions. Of course, many of these enterprises face challenge in assessing the benefits. This is where enterprises need help.

How is Industry 4.0 reshaping manufacturing?

Industry 4.0 is driving improvement in productivity and efficiency; hence it enables producing more with less costs. Plants are back to three shifts and there is enough pressure on increasing capacity. Expansion is not the solution always, there is a lot that can be done to improve the capacity by optimizing the use of resources. Plants have a good automation in place, need is to connect the equipment with each other and to the worker so that data driven real time decisions can be taken. Human and Machines collaborating is just like making one plus one eleven which makes the outcomes also transformational.

How do you envisage the role of “NASSCOM” in this transition?

NASSCOM CoE, Gandhinagar center has built India’s largest ecosystem for the manufacturing digitization by bringing together enterprises, startups, researchers and government on a common platform. We are running several initiatives for this ecosystem to create awareness on value of digital and enable companies co-create solutions working with startups and technology companies. Manufacturing Innovation Challenge has been our flagship program for large enterprises to find solutions to complex manufacturing challenges. We also have dedicated programs for the MSMEs with name of Udyam 4.0 – Nayi DISHA which are aimed to guide MSMEs on where to start and how to start. We have developed a first of a kind virtual Smart Manufacturing Competency Center which is a platform to enable manufacturing leaders experience diverse range of Industry 4.0 solutions being showcased by innovative solution providers. Last three months, I spent considerable time with MSME leaders through digital awareness sessions, one to one engagement and doing plant assessment and it is clear that this sector needs bigtime support from the ecosystem.

In case you missed:

- None Found

1 Comment

Thank you for sharing the information about India always ready to embrace industry 4.0, it is good article , keep sharing.