These regulations, implemented in two phases, impose stringent criteria on battery pack design and performance.

The emergence of electric vehicles represents a significant and necessary advancement in transportation, offering a more sustainable and environmentally friendly option compared to traditional gasoline-powered vehicles. However, as with any innovation, safety concerns accompany the adoption of electric vehicles.

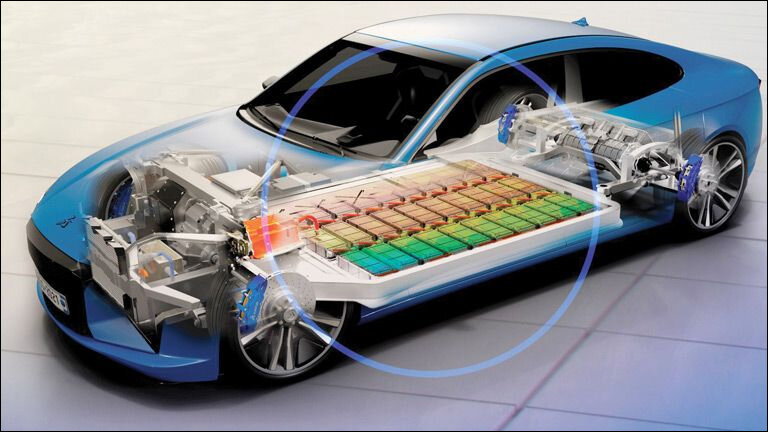

A pivotal aspect of ensuring the safety of electric vehicles is the integrity of their batteries. Serving as the core component, batteries supply the necessary power to propel the vehicle. Therefore, guaranteeing the safety of these batteries is paramount to safeguarding passengers and promoting the widespread adoption of electric vehicles. This underscores the critical role of battery certification, which remains a top priority for governments and manufacturing entities alike.

Battery Certification – What does it mean?

Battery certification is a rigorous procedure conducted by an independent third-party organization to assess and verify the safety and performance of a battery. This process encompasses a range of tests, including electrical, mechanical, and environmental assessments. The primary objective is to ascertain that the battery meets stringent industry standards and regulations, ensuring its reliability and safety for use in various applications, including electric vehicles, consumer electronics, and renewable energy storage systems.

Is Battery Certification Important and Why?

Battery certification plays a crucial role in safeguarding the safety of electric vehicles (EVs). Given the large size and potent power of EV batteries, malfunctions can pose significant risks. Certification ensures that these batteries adhere to rigorous safety standards, including resistance to extreme temperatures, vibrations, and prevention of short circuits. Moreover, certification entails stringent quality control measures, minimizing the likelihood of failure and enhancing battery reliability.

Furthermore, these certification tests instill confidence in consumers regarding the safety and dependability of EVs. Knowing that their vehicle’s batteries have undergone thorough testing and meet stringent safety criteria provides reassurance to consumers, ultimately bolstering their trust in electric vehicles as a safe and reliable mode of transportation.

Who Provides Battery Certification?

Battery certification services are offered by various organizations worldwide, ensuring compliance with stringent safety standards. Globally recognized entities such as UL (Underwriters Laboratories), TUV (Technischer Überwachungsverein), and Intertek are prominent providers of battery certification.

In India, electric vehicle battery providers must obtain ARAI certification under the AIS 156 amendment. The Automotive Research Association of India (ARAI) possesses extensive expertise in testing and certifying products and components for their safety and performance. This certification ensures that electric vehicle batteries meet the necessary standards and regulations for safe operation in the Indian market.

Apart from private organizations, government bodies and regulatory authorities play a crucial role in battery certification. In India, the Ministry of Road Transport and Highways (MoRTH) has taken proactive measures to address battery safety concerns in electric vehicles. Effective from October 1, 2022, MoRTH has introduced new battery safety norms under the updated regulations AIS-038 Rev 2/AIS-156. These regulations align with EU standards and encompass comprehensive tests including environmental and thermal propagation tests. This proactive approach ensures that electric vehicle batteries adhere to stringent safety standards, promoting the safe and sustainable adoption of electric vehicles in India.

All Encompassing Details on Battery Safety Regulations in India

The introduction of the new battery safety norms is a direct response to a series of fire incidents linked to defective batteries, reported by prominent electric two-wheeler manufacturers such as Okinawa, Ola Electric, and Pure EV in April 2022. The industry has embraced these regulations, expressing optimism that they will significantly improve the safety and dependability of electric vehicles in India. This, in turn, is expected to foster increased adoption of EVs across the country.

The updated regulations impose rigorous criteria on battery pack design, onboard chargers, and thermal propagation, aimed at mitigating the risk of fire due to internal cell short-circuiting, among other factors. Moreover, the requirements encompass traceability of packs, the inclusion of an additional safety fuse, protection against regenerative braking, appropriate cell-to-cell spacing, and the incorporation of a microprocessor-based Battery Management System (BMS) equipped with all necessary protections. These regulations are being rolled out in two phases, with Phase 1 commencing on December 1, 2022, followed by Phase 2 scheduled to commence on March 31, 2023.

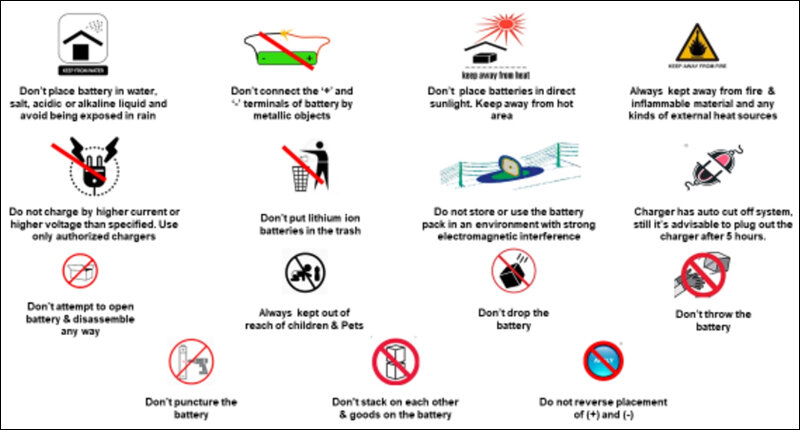

Various tests for battery safety will be compulsory for different vehicle categories. The L category, comprising two and three-wheelers, will undergo tests including vibration tests, thermal shock tests, cycling tests, mechanical drop tests for removable REESS (Rechargeable Energy Storage Systems), fire resistance tests, external short circuit protection tests, overcharge protection tests, over-discharge protection tests, over-temperature protection tests, and hydrogen emission tests.

In contrast, M&N category vehicles, encompassing four-wheelers, eight-wheelers, and more, will undergo all the tests mentioned previously, in addition to thermal propagation tests and hydrogen emission tests. The thermal propagation test evaluates the extent to which a thermal event can propagate within the battery pack, while the hydrogen emission test quantifies the amount of hydrogen gas released during such an event.

As electric vehicles gain increasing popularity, battery certification remains a critical aspect of ensuring EV safety. Therefore, the Indian government’s rollout of new battery safety norms and the enforcement of rigorous testing standards across various vehicle categories represent significant strides toward bolstering EV safety in the nation. These updated regulations and testing protocols are poised to mitigate the risk of fire-related incidents, fostering greater consumer trust and confidence in electric vehicles.

The article emphasizes the vital role of battery certification and India’s new regulations in ensuring the safety and reliability of electric vehicles (EVs). Battery certification, conducted by third-party organizations, validates the safety and performance of EV batteries through rigorous testing. The Indian government’s introduction of updated battery safety norms, effective from October 1, 2022, aligns with EU standards and includes comprehensive tests to address safety concerns.

These regulations, implemented in two phases, impose stringent criteria on battery pack design and performance. Tests mandated for different vehicle categories ensure compliance with safety standards, promoting EV safety and consumer confidence. By addressing fire incidents associated with defective batteries and enhancing safety measures, the regulations aim to foster greater adoption of EVs in India.

Overall, the proactive approach taken by regulatory authorities and industry stakeholders underscores the commitment to EV safety and sustainability, heralding a promising future for electric mobility in India.