When Kaynes Semicon got greenlit by the India Semiconductor Mission in April 2024, most assumed the usual two-year delay curve would follow. Instead, the company pushed ahead at warp speed.

About a month ago, we posted about India’s first Aatmanirbhar semiconductor chip, followed by our first Aatmanirbhar chip fab led by TATA. Now we’re back with another critical milestone in India’s semiconductor story. In July 2025, Kaynes Semicon, one of five OSAT firms backed by the India Semiconductor Mission, will deliver India’s first paid chip prototype to U.S.-based Alpha & Omega Semiconductor (AOS). It’s not a test unit or a trial. It’s a full-grade, customer-funded prototype destined for field validation.

Manufactured entirely within India’s Sanand facility, including packaging, assembly, and testing, this chip is a small package with a big message: India’s semiconductor pipeline is no longer just potential, it’s operational. And with a five-year offtake deal already in place, Phase I of Kaynes’ 70-acre facility is expected to ramp up to 1.5 million chips per day by early 2026. India’s foundry dreams just found their first paying customer.

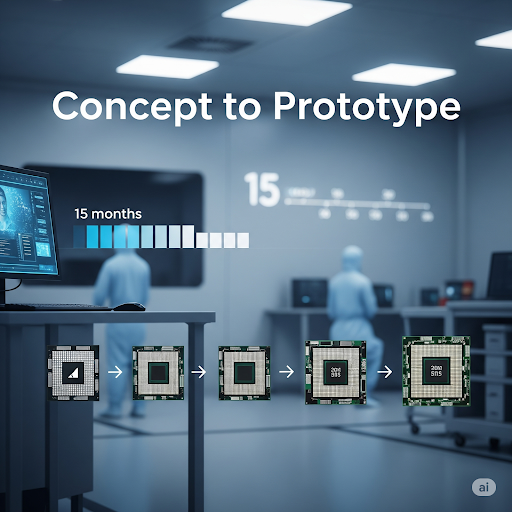

From Approval to Prototype in 15 Months

When Kaynes Semicon got greenlit by the India Semiconductor Mission in April 2024, most assumed the usual two-year delay curve would follow. Instead, the company pushed ahead at warp speed. By mid-2025, its cleanroom pilot line in Sanand was not only ready, it was producing paid prototypes. The chip in question is bound for Alpha & Omega Semiconductor, a Nasdaq-listed player with a serious track record in power and mobile ICs.

What makes this deal remarkable is that it’s not a government-brokered batch or proof-of-concept; it’s a full-fledged, customer-specified order under a five-year offtake agreement. That means predictable volume, recurring revenue, and long-term validation. This is the first Indian OSAT company to send a chip out the door with a commercial buyer lined up, and that’s a major milestone.

Even more encouraging is what Kaynes is building next. The Phase I facility, now functionally operational, will ramp up to 1.5 million chips per day by Q1 2026, with packaging lines for flip-chip BGA, QFN, and CSP formats. Equipment installation is reportedly ahead of schedule. AOS will account for over 60% of that initial capacity, giving Kaynes a rock-solid base load as it scales.

The company is also in parallel talks with Qualcomm, Broadcom, Intel, STMicroelectronics, ROHM, and Infineon. In other words, this isn’t a one-client story, it’s the first domino. Kaynes’ Phase II planning is already underway, with land and expansion scope built into the original 70-acre blueprint. And now that the first chip’s been sold, investor interest and foreign customer confidence will only go one way: up.

Why This Matters for Aatmanirbhar Silicon

India’s semiconductor narrative often stalls at MoUs or ceremonial laying of foundation stones, but Kaynes Semicon’s move flips that script. This is the first time a locally backed OSAT company has fully assembled, tested, packaged, and sold a commercially qualified prototype, taking real money from US-based AOS in a structured, five-year offtake agreement.

Additionally, Sanand’s pilot line that spans over 1,000 m² of cleanroom space, hit this milestone just 15 months after being approved under the India Semiconductor Mission in late 2024. That means Indian engineers ran the full backend pipeline, from substrate to shipping, proof that homegrown talent, when properly incentivized, can execute at world-class speed.

It also rounds out efforts under the SEMICON India and SPECS programs, which offer up to 50% capex support, putting Kaynes not just on the map, but at the front of the class, anchoring a pathway for future scale and global competitiveness.

Kaynes isn’t stopping at prototypes, it has already moved to deepen its OSAT footprint with a dedicated R&D center focused on power-semiconductor packaging in Sanand. This follows the acquisition of a production-ready power-module line from Fujitsu, which included access to process recipes, cleanrooms, and lab equipment, effectively transferring both capabilities and technical expertise to Indian soil. That gives Kaynes a shortcut into high-margin backend services for automotive, renewable energy, and EV applications, without the years of trial and error usually needed for qualification.

Combined with its planned PCB plant in Chennai and MoUs with states like Telangana and Karnataka for 12 OSAT lines, Kaynes is stacking capability on capability: prototypes today, power packaging tomorrow, and ecosystem confidence thereafter. This layered expansion aligns perfectly with India’s wider push under the ISM and SPECS programmes to support up to 50% capex, strengthen local supply chains, and build talent pipelines across OSAT and ATMP segments.

Transforming India’s Silicon Landscape

Kaynes Semicon’s delivery of a fully paid prototype is more than just a milestone, it’s a keystone. It proves that indigenous OSAT infrastructure can execute end-to-end assembly, testing, and packaging at global standards, with real clients and real orders. Now, with power-module R&D, PCB integration, and multi-line expansion plans in flight, Kaynes is moving from “proof” to “platform.” That creates a ripple effect: global players gain confidence, investors see capacity, and India’s semiconductor ecosystem takes measurable shape beyond hopeful rhetoric.

If the company hits its Phase II targets next year, Kaynes will have shifted perception and production from “design hub” to manufacturing powerhouse. And in a global industry backed by a $150 billion national market forecast and backed by aggressive state incentives, that pivot isn’t just strategic, it’s transformative.

In case you missed:

- 4 New Chip Fabs and a Rallying Cry from The Red Fort!

- India’s first Aatmanirbhar Chip Fab: TATA leads the way!

- Tata Electronics to Manufacture Intel Chips & AI Laptops in India!

- India’s first Aatmanirbhar semiconductor chip is finally here!

- Aatmanirbhar Push: India Becomes 7th Nation to Crack Gallium Nitride Chip Technology

- One Chip to Rule Them All: The 6G Chip at 100 Gbps!

- QpiAI Unveils Kaveri, India’s First Aatmanirbhar 64-Qubit Quantum Chip

- The Sodium-Ion Breakthrough That Could Unplug Lithium’s Reign

- Quantum War Tech: DRDO and IIT help India take the lead!

- India, iPhones, China & Trump: The Foxconn Story!